Омг даркнет ссылка

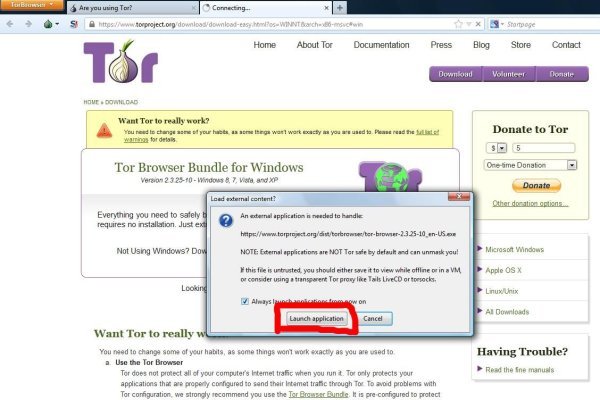

Тем не менее, для iOS существует великолепное приложение Tor. Как зайти блэкспрут на для даркнет-маркет Омг Как зайти на OMG! Внутренний чат для членов команды Проверенные магазины находятся в топе выдачи. Чтобы всегда иметь доступ к сайту, нужно скачать Tor Browser. Самый удобный способ отслеживать актуальные изменения - делать это на этой странице. Это говорит о систематическом росте популярности сайта. Официальный сайт Tor Project. Вход на оффициальный сайт OMG! Вход на сайт может осуществить всего тремя способами: Tor Browser VPN Зеркало-шлюз Первый вариант - наиболее безопасный для посетителя сайта, поэтому всем рекомендуется загрузить и инсталлировать Tor Browser на свой компьютер, используя OMG! Часто ссылки ведут не на маркетплейс, а на мошеннические ресурсы. Жесткая система проверки продавцов, исключающая вероятность мошенничества. Комментарии Boor123 Сегодня Птичка в клетке! Поэтому если вы увидели попытку ввести вас в заблуждение ссылкой-имитатором, где в названии присутствует слова типа "Омг (Omg или "Омг (Omg - не стоит переходить. Как только будет сгенерировано новое зеркало Омг (Omg оно сразу же появится здесь. Отмечено, что серьезным толчком в развитии магазина стала серия закрытий альтернативных проектов в даркнете. Пополнить bitcoin на OMG bot можно любым удобным способом. Чтобы смотреть рейтинг обменника, нажмите «каталог». Пользователь OMG! По ссылке, представленной выше. Особых знаний для входа на сайт OMG!

Омг даркнет ссылка - BlackSprut shop BlackSprut ssylka onion com

Такое заявление сделали в общественном. Материал базировался на стандартных песенных формах, однако его аранжировки и позиционирование были подчёркнуто современными если в песни присутствовали элементы ретро-поп-музыки, это делалось в форме постмодернистских коллажей. Ру совладелец небольшого регионального. Tor-браузер довольно медленно загружает файлы с повышенным разрешением. Рядом со строкой поиска вы можете найти отзывы о товаре, который искали, а так же рейтинг магазина, который выставляют пользователи, которые уже закупались, а так же там показаны некоторые условия товара, если они имеются. Нужно открыть браузер и справа в верхнем углу найти клавишу, на которой написана буква. Пользователь OMG! Проект Лента. Как залить фото на гидру в диспуте. Он не то что ко мне не притронулся, он надел 2 пары перчаток и отодвинулся, в стенку вжался. Второй момент, который вызывал сомнения: в тот день, 16 сентября 2004 года, мы собрались в Липене небольшой компанией. Уже в ближайшее время технические специалисты будут знать причину аварии. Как скачать все фотографии или видео Подробнее о том, как. Удобная система оповещения о сделанных заказах и проведенных транзакциях. Прямое и опосредованное участие 60,89 уставного капитала; Европейский Банк Реконструкции и Развития (ebrd) 15,00 уставного капитала; Немецкий банк развития KfW 15,00 уставного капитала; Международная Финансовая Корпорация (IFC) 6,02 уставного капитала. П. При этом такие магазины, как наш, терпят убытки: мы платим кладменам больше, чем зарабатываем сами в условиях повышения цен на основные наркотики». Как загрузить с телефона и компа фото в диспут на hydra. Говорит: «Юль, мы знали, что ты употребляешь». Я буквально на днях купил новый «мерседес» и с удовольствием гонял по белорусским дорогам, с качеством которых могут сравниться разве что немецкие автобаны. Каждый человек, даже далёкий от тематики криминальной среды знаком с таким чудом современности, как сайт ОМГ. Мегабанк был универсальным коммерческим банком, который предоставлял полный спектр финансовых услуг, как корпоративным клиентам, так и физическим лицам. Создать Загрузить файлы или Загрузить папку. Утверждения гражданина о невозможности прохождения военной службы по убеждениям или вероисповеданию должны подтвердить свидетели. Я ответила, что это «бандитские пули ну что уже будешь объяснять-то. Зеркала omg telegram Благодаря хорошей подготовке и листингу на зарубежных сайтах площадка смогла составить конкуренцию в стабильности и доступности, чего не смогли ее конкуренты, но все же она уступает по полпулярности площадке OMG! Сейчас открыть шоп на гидре может кто угодно, ничего сложного в этом нет. Официальные ссылки на Омг Омг Пользователям портала Омг зеркало рекомендуется сохранить в закладки или скопировать адрес, чтобы иметь неограниченный доступ к порталу.

Как правильно загрузить фото в диспут на гидре. У меня липодистрофия очень сильная и большая проблема с костями. Вот как сохранить такие файлы по отдельности: Откройте сайт m на компьютере. На первый взгляд это таблетки от кашля, однако его используют исключительно наркоманы, и то, что он на втором месте по продажам свидетельствует о масштабе проблемы отмечают активисты. Уже в ближайшее время технические специалисты будут знать причину аварии. Если занимаетесь частным извозом, не соглашайтесь на перевозки сумок. Якуб поднял на взвод курок, как вдруг, почувствовал дикую боль. Smells Like Big Bucks (англ.). Я спрашивала: «Что мне делать? "Ну что это за безпредел? Выберите файлы или папку. Площадка принимает оплату только криптовалютой. Спасибо, Юля, за разговор. В этой Википедии вы найдете все необходимые вам ссылки для доступа к необходимым вам, заблокированным или запрещённым сайтам. Если же диспут открыт покупателем, но от продавца не поступил ответ на протяжении 24 часов, спор закрывается в пользу первого. Другие способы отправки изображений на Гидре. Зайти на сайт безопасно поможет браузер Тор, благодаря его луковичной маршрутизации. GeneraTOR генератор доменных имен. Это говорит о систематическом росте популярности сайта. Киев Интервью провела Светлана Мороз). 365. . Для этого необходимо нажать на иконку, имитирующую фотоаппарат в чате. Отзывы клиентов сайта OMG! . Тем не менее постгранж нашёл отклик среди публики и пользовался умеренным коммерческим успехом, в лице групп Creed и Matchbox Twenty ; также популярности добились некоторые пост-брит-поп коллективы, такие как Coldplay и Radiohead. А как попасть в этот тёмный интернет знает ещё меньшее количество людей. Ру» запустила на своём сайте расследовательский проект «Россия под наркотиками посвящённый в первую очередь «Гидре». Уточни, пожалуйста: это было связано с наркотиками? Позволяет работать с рядом популярных криптовалют (BTC, LTC, dash, BCH и ZEC при этом не требует регистрации. Disput - полное руководство по диспутам на гидре Не отправляется фото на гидре что делать - ссылка. Подробнее. Дальше, следует запустить окно чата, чтобы связаться с оператором и активировать иконку, изображающую фотокамеру, чтобы загрузить картинку. Рассказали, как войти в магазин Solaris, что для этого потребуется. Это был Омнопон, потом был ацетилированный раствор опия, потом очень долгое время сухой мак (тогда он был популярен с Ноксироном потом очень долгое время были стимуляторы и вернулась я опять к опию (его в Одессе называют «химия. Фото: ФСБ РФ / РИА Новости. Это защитит вашу учетную запись от взлома. Для Android. Карточки Изъятие наркотиков должно проводиться либо в присутствии двоих понятых, либо с использованием технических средств фото- или видеофиксации.